The goods of today are the resources of tomorrow at yesterday’s resource price.

That is the belief underpinning the industrial system known as the circular economy, a topic gaining popularity as the solution to such global challenges as pollution, climate change, and the loss of biodiversity.

Supported by three main tenets – eliminating waste, extending the longevity of products and materials, and regenerating natural systems – the circular economy aims to improve the health of our people and planet while creating jobs and prosperity.

In the circular economy, everything we produce is eventually used for another purpose instead of being thrown away. This cycle continues indefinitely, which significantly reduces waste and the need to produce new commodities. As a result, we can greatly reduce manufacturing processes that emit harmful greenhouse gases and alleviate the strain on our natural environment (because we no longer need to extract raw or virgin material from the earth).

What are the benefits?

The circular economy was designed to make sure humans around the world experience a prosperous future where necessities are abundant. The circular economy helps:

- The environment: fewer carbon dioxide and greenhouse gas emissions improve air quality and regenerative farming techniques improve soil health and increase biodiversity.

- Businesses: reduced reliance on virgin material lowers businesses’ exposure to volatile raw material prices; demand for new products and services related to logistics, remarketing, refurbishment, and remanufacturing introduces new revenue streams.

- People: better air and soil quality improves health and reduces healthcare costs; access to more durable products increases their utility and lowers the total cost of ownership for consumers.

- The economy: reduced dependence on raw material mitigates risks related to price volatility and availability; creation of new products and services sparks innovation and technology advancement.

How does Miller contribute to the circular economy?

Waste Diversion Specialists

One of Miller Waste System’s specialties is diversion of waste from landfills. When products sit in landfills, we lose the opportunity to recover valuable material, including steel, wood, and concrete from them. As a result, when we need to use these materials again in other products, we must extract them from the earth using harmful, unsustainable practices.

Did you know that, of the 300 million metric tons of plastic produced globally each year, only 12% is reused or recycled? The vast majority is incinerated, landfilled, or dumped into the oceans, where its value is permanently lost. Of the 54 million tons of electronic waste we produce globally each year, only 17.4% is recycled. E-waste, if mismanaged in a landfill, can leak toxins and threaten the health and ecosystems of local communities. 1

Miller helps businesses and communities recapture the value of important resources by diverting as much waste from landfills as possible, recycling or composting them instead.

Recycling Expertise

We design, build and operate Material Recovery Facilities (MRFs) that receive, sort and process recyclables, and we the sale and transportation of these products to end-market customers. Our MRFs can process an excess of 200,000 tonnes of recyclable material annually such as plastics, paper, cardboard, steel, aluminum, and glass. Miller then distributes the sorted materials to various manufacturers around the globe based on demand for recycled products. Learn more about our recycling process here.

Supplier of Secondary Material

Our dedicated team of in-house experts ensure recycled products are reprocessed to their highest end-use. Once the recyclable materials are sorted, they are individually recycled or remade into new products depending on demand, which ultimately reduces the need to harvest new materials. Miller is a major supplier of secondary material in the commodity marketplace, contributing to the final step in the circular economy cycle.

Waste-to-Energy Initiatives

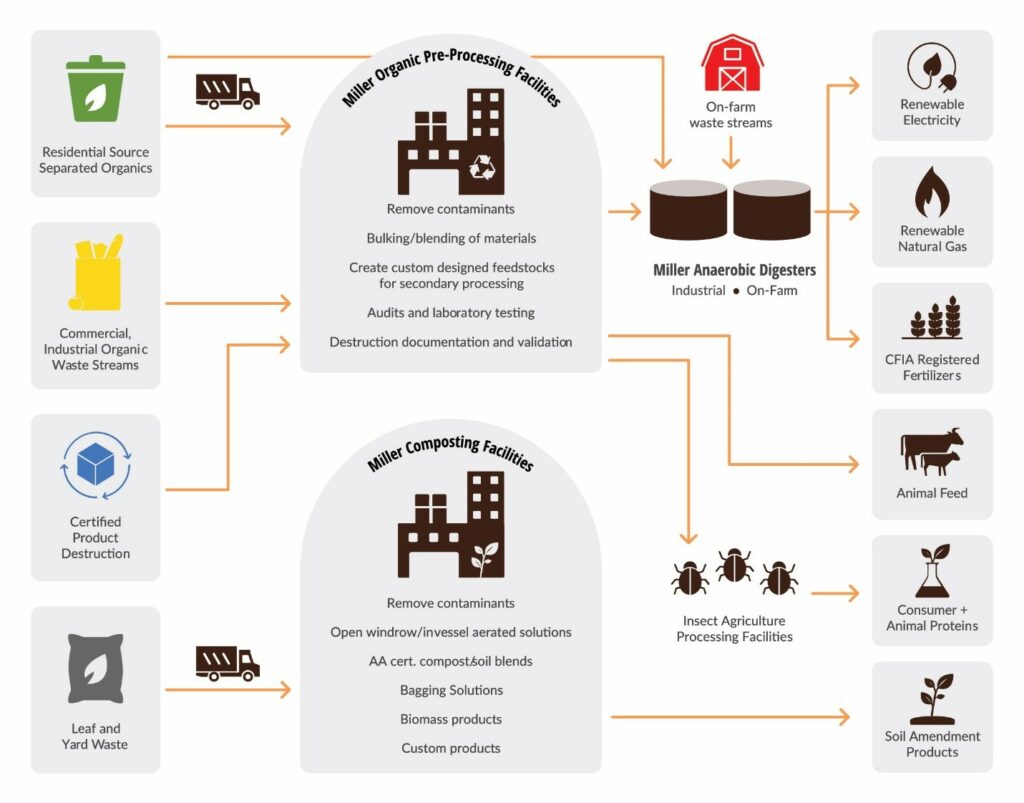

Miller Waste System’s waste-to-energy facility takes organics, leaf, and yard waste from residential, commercial, and industrial sources and sustainably processes and transforms it into electricity, natural gas, CFIA-registered fertilizers, soil, and mulch via anaerobic digestion. This electricity is fed into the Ontario electrical grid under the provincial renewable feed-in tariff program, the equivalent to powering 830 Canadian homes per year with clean, renewable electricity.

It’s estimated that harnessing organic waste streams, which contain high levels of nitrogen and phosphorus, alone could unlock upwards of USD 700 billion for cities globally.2

See diagram below for further information.

We recognize that a circular economy expands beyond just waste management and requires the support of many other key members of our community. We want to know – what are you doing to contribute to our zero-waste goal?

1 5 Opportunities of a Circular Economy | World Resources Institute (wri.org)

2 Five benefits of a circular economy for food (ellenmacarthurfoundation.org)