Miller takes care of our communities, customers, people, and the environment.

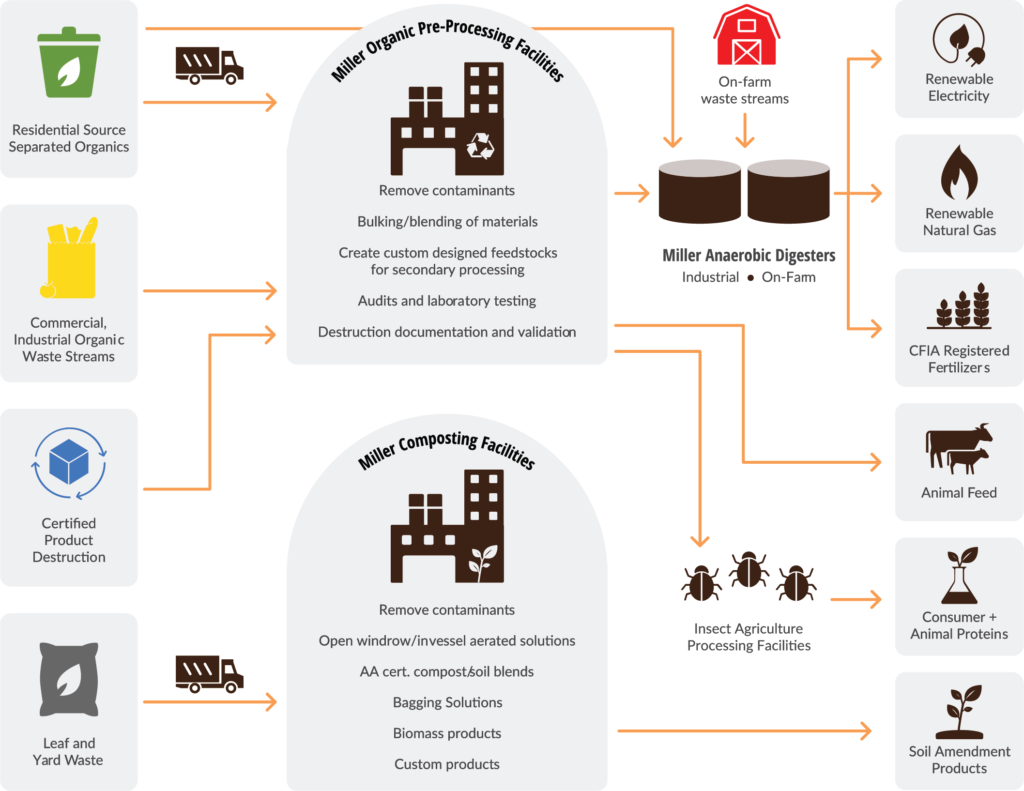

Our extensive resource recovery ecosystem includes solutions designed to help customers meet their environmental targets in a transparent, cost-effective manner.

Customer Focused Solutions

- Cost effective landfill avoidance solutions for all organic waste streams

- GHG impact assessments and valuations

- Detailed data and auditing solutions and analysis for customers ESG

- Full customer transparency and visibility into material flow

- Simplified billing

- Custom engineered solutions

Innovative Material Recovery

At Miller Waste Systems, we are committed to innovation in material recovery. Miller uses equipment that separates the organic material from the plastics thereby allowing the different materials to be recycled appropriately.

How it Works

This machine stands as a horizontal mill that has 52 swinging hammers that spin at high speed. These swing hammers smash the product and push the organics down through screens into a collection auger. With the help of this new technology, Miller Waste contributes towards improving the environment by being able to sort through organic waste to further increase the quantity of compostable items. This means more nutrients to soil, and less waste in the landfills!

Anaerobic Digestion

The NS COMFIT program resulted in several wet-AD facilities being built in Nova Scotia. These. Wet-AD facilities require high-energy feedstocks to generate the biogas that is combusted to generate renewable electricity. To combat the amount of energy these facilities require, Miller has installed pre-processing equipment at our Dartmouth facility to turn the commercial food waste into material that can be fed to the wet-AD facilities. By doing so, we will be contributing to help produce renewable electricity. Miller Waste will soon have similar capabilities and capacity in the GTA market!

This machine is able to process mixed commercial and residential organic materials.

This technology allows us to mechanically separate the organic waste from its packaging. Packaging is then diverted via another auger into a collection bin.

Liquid is then added to the collection bin to turn the organic paste into a pumpable slurry.

Slurry is then loaded into tanker trucks and sent to the AD facility. Download our PPT to learn more.

Gordon Food Service Letter To Miller

Ready to discuss waste solutions?

Contact us today for our best-in-class customized solutions.

Miller Waste Systems Businesses

We are proud of our growing family across Canada.

Miller Waste Systems

We operate 1,000 collection vehicles and employ over 2,000 trained personnel. We manage the complete waste stream with innovation and safety standards as our top priorities in our daily operations.

Learn More

Escarpment Renewables

Escarpment Renewables is a waste to energy facility that receives and transforms on farm and commercial organics to a reusable high energy product that is applied to our local crops. This electricity is fed into the Ontario electrical grid under the provincial renewable feed-in tariff program, the equivalent to powering 830 Canadian homes per year with clean renewable electricity.

Learn More

Miller Environmental

Miller Environmental Corporation is the only Hazardous Waste Management company of its kind in Manitoba.

Learn More